Making machines better every day is our claim. And also the wish of our customer: Lacom GmbH has been developing laminating and coating systems for over 40 years. Together we have been finding solutions to make applications better and increase service life for 20 years.

Lacom GmbH and Christian Maier GmbH & Co. KG pursue the goal of producing customized solutions of the highest quality and with the greatest possible reliability. The joint view into the future of mechanical engineering is also in focus and is constantly being developed further.

Particularly in focus: to clearly process the throughput data in real time.

With the sophisticated sensor technology of Christian Maier GmbH & Co. KG, the data is recorded directly at the machine and converted into a digital signal via Link C. The data can then be processed in real time. This allows the data (such as speed, pressure, temperature, wear, leakage, torque) to be clearly transmitted to a dashboard in real time. It allows us to evaluate the data to identify the performance of the machine and perform accurate predictive maintenance of the rotating union.

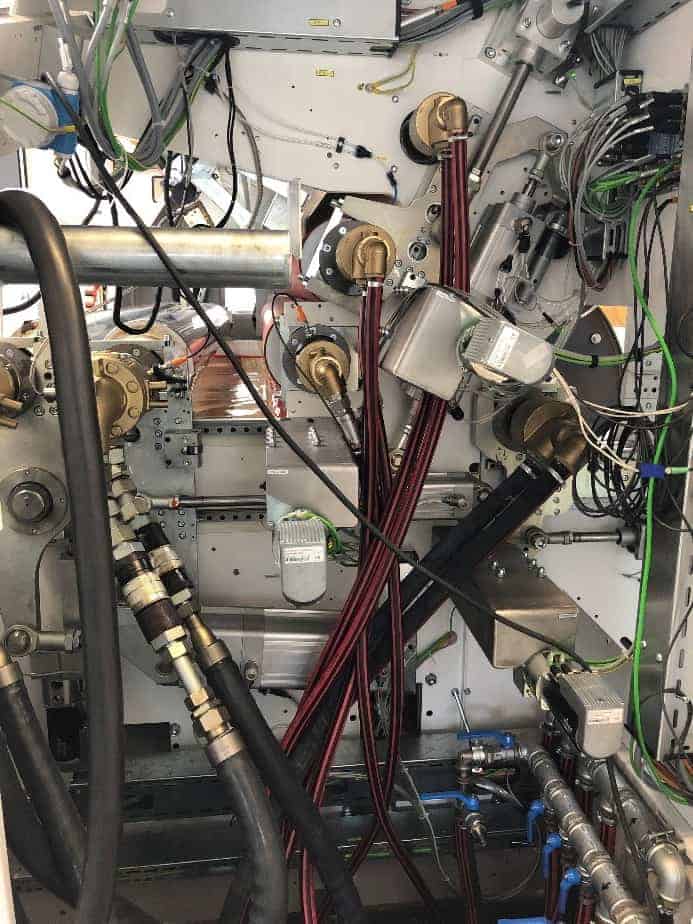

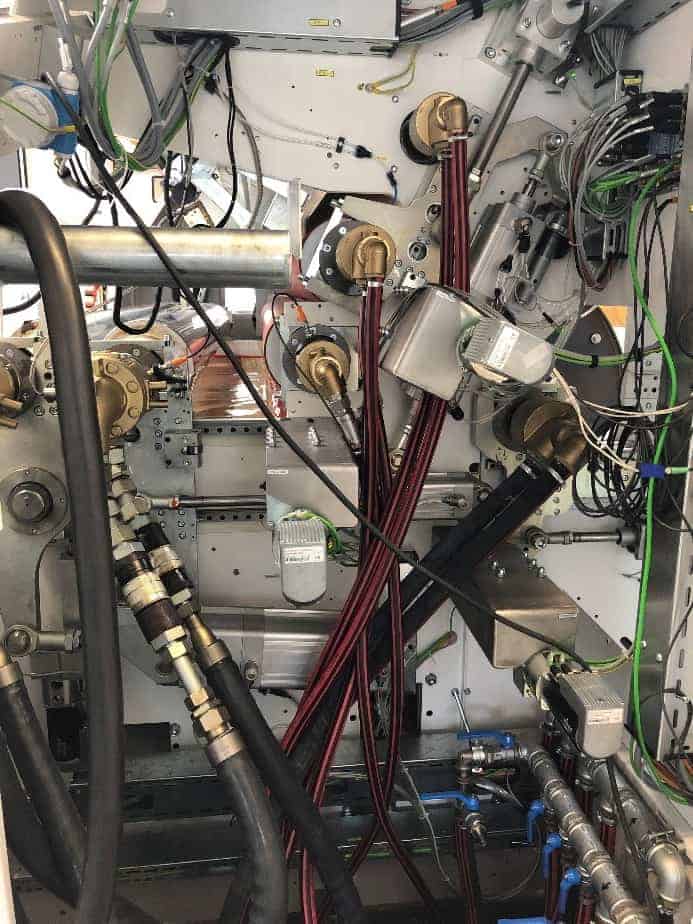

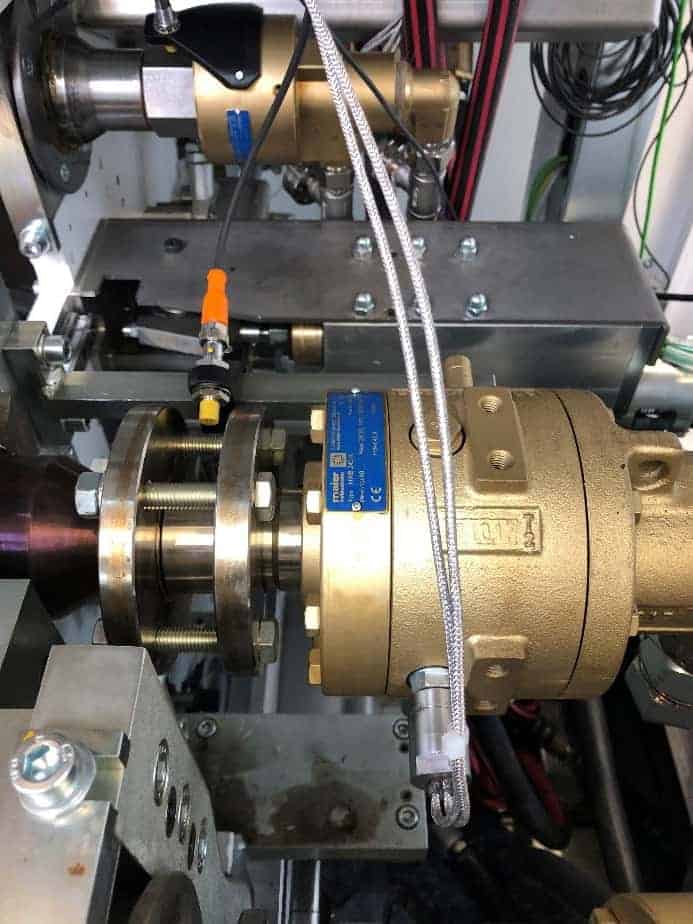

After a successful test phase (R&D) of the sensor technology at Christian Maier GmbH & Co. KG, Lacom, together with Mr. Winkler and Mr. Kühn, installed three measuring devices at a test facility to further test the sensors in the production environment.

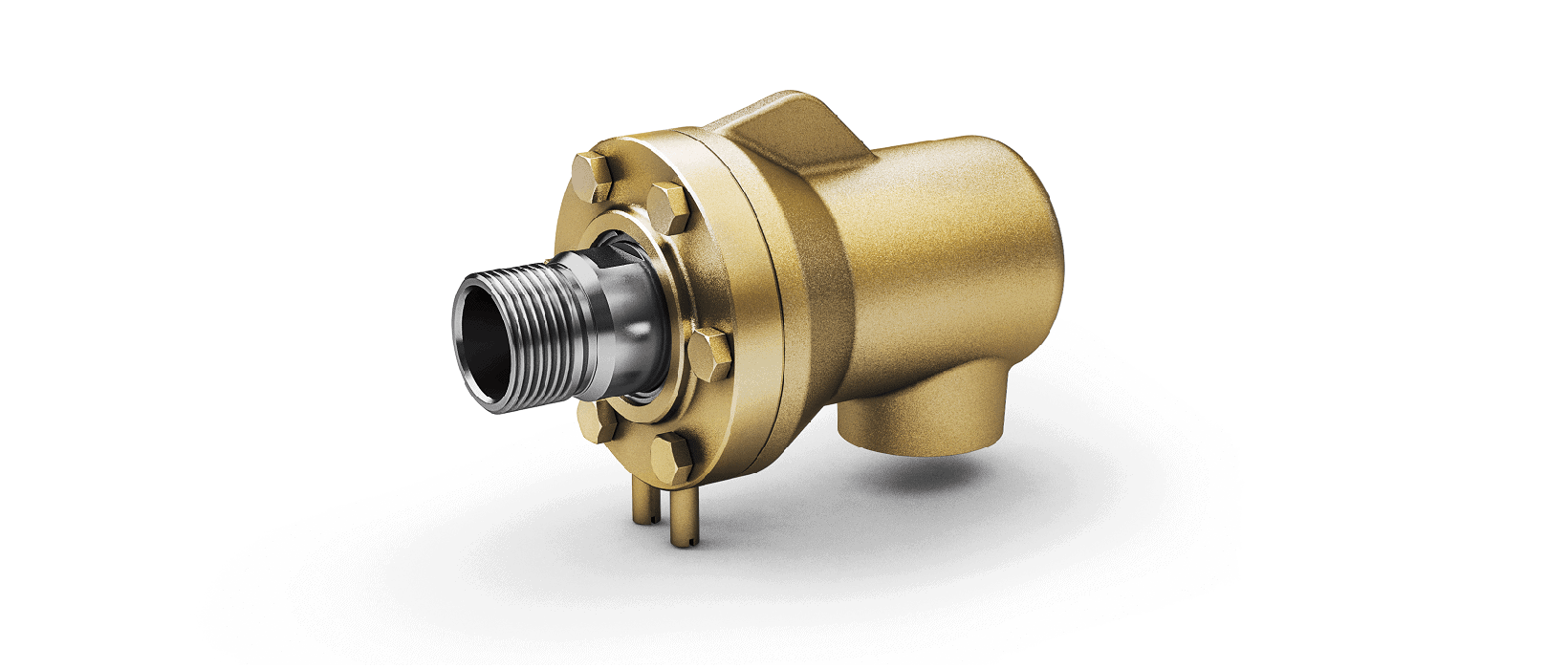

A pressure/temperature sensor (Sense P/T [pressure/temperature]) and a speed sensor (Sense S [speed]) were installed on the application roller of the HWB 240 K rotating union on the test/laboratory system, which is designated EVOlution 2400 from Lacom. A speed sensor (Sense S [speed]) is installed on the counter pressure roller of the DP 40 R 53 rotating union. To convert the data into a digital signal, our “Link C” was used. The data are transmitted in real time to Heidenheim to control the evaluations and to gain knowledge from the field operation.

“When choosing our partner, it was important to us that we see eye-to-eye, speak the same language and that distances are short. At the same time, however, our partner must have expertise at worldwide locations and deliver precise quality. We found all of this at Christian Maier GmbH & Co. KG Maschinenfabrik. We are thrilled with the excellent service, the outstanding quality. This helps us to drive innovation and make our machines more durable.”

Lacom GmbH, Mr. Winkler and Mr. Kühn

PT Dyrec Anugrah Sentosa was established in 2019 in South Tangerang. Our company sells manufacturing equipment parts which are often called rotary joints or rotary unions. Even though it is relatively new, our team has years of experience in this field until we are trusted to be the sole agent of the German company, Maier. Manufacturing companies related to paper production, printing and packaging are our target market in Indonesia.